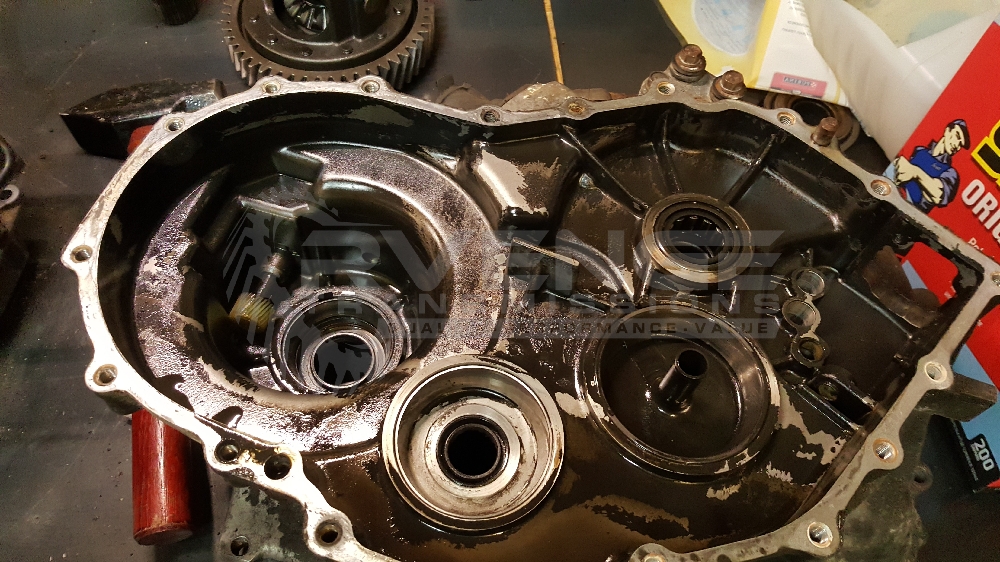

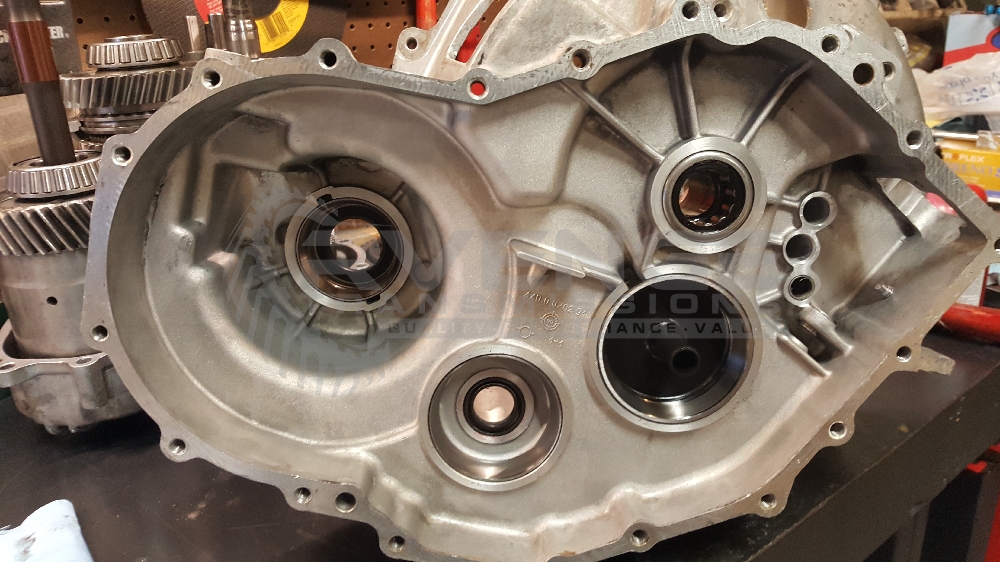

Seeing inside many transmissions of various condition, mileage, and, age you begin to see all the common problems. Worn synchronizers, bad bearings, leaking seals, even cracked or broken transmission cases are regular occurrences.

Normally we are rebuilding transmissions that either grind, make noise, leak, or just don’t feel good anymore. Every once in a while we get something slightly different.

This customer said his car was popping out of 6th gear. Its unusual for a Getrag to pop out of gear unless it has fork damage or shift selector damage.

Very often the roll pin will work out of a fork or even the shifter assembly tower on the top of the transmission.

Sometimes people will believe a bad synchronizer will cause a transmission to fall out of gear and when they are speaking of the synchronizer friction ring, this is just not the case. Once a shift is completed the synchro ring is just along for the ride.

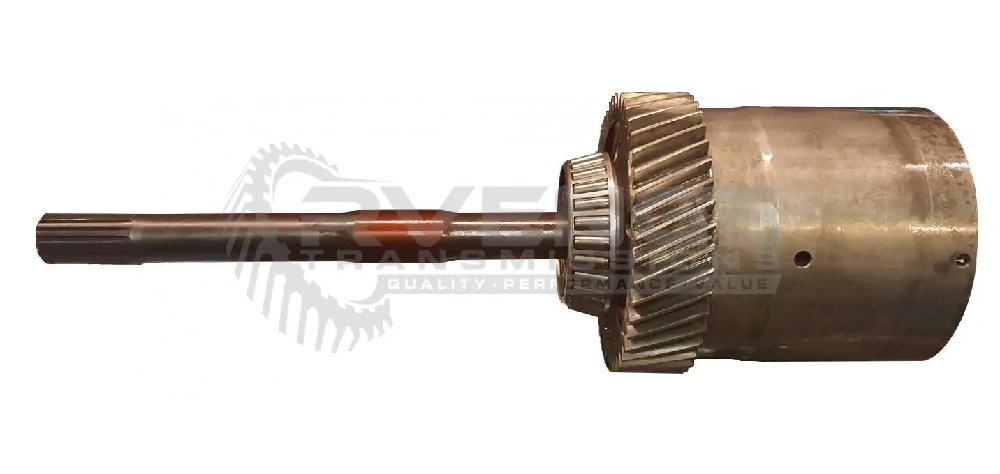

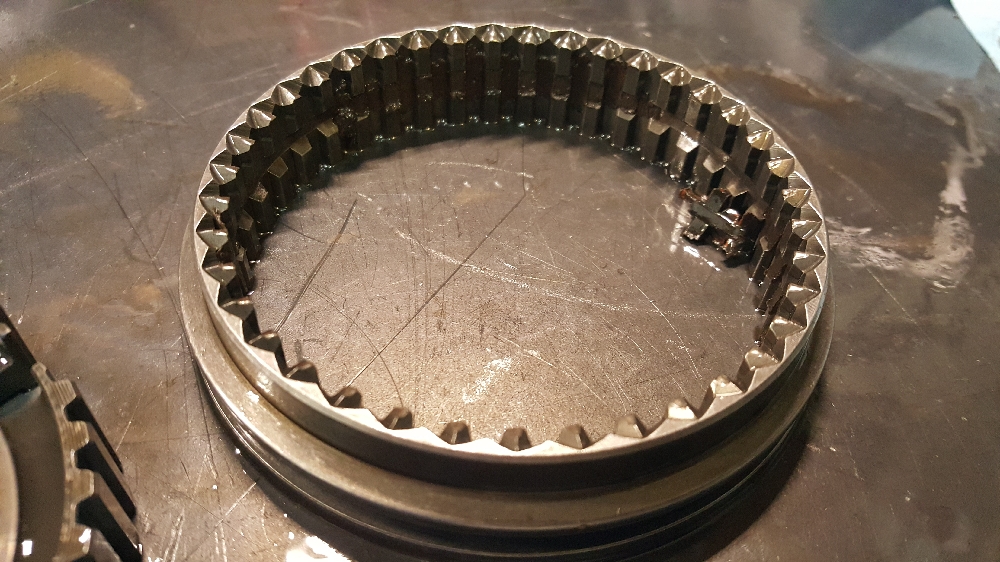

After ruling out the common causes a very close inspection of this transmissions 6th gear revealed the cause of the transmission popping out of 6th.

Engagement Teeth Damage

Engagement teeth wear was causing this unit to pop out of 6th under any kind of load. There is a back taper to these engagement teeth that is designed to actually make the slider push towards the gear, further into gear undo load. If this is worn away it will pop out of gear and you will not be able to hold it into gear.

It’s very common to see the points worn off the top of the engagement teeth, which causes hard shifting, but this is an un-common place to wear, especially for 6th. The unit in question did have high miles. Paying attention to details like this is what makes for a successful rebuild.