Fuel Pumps

The stock fuel pump on the 3000GT VR4 and Dodge Stealth R/T Turbo is a reliable unit, but very limited in performance/flow and is now 25 to 30 years old.

The stock pump is limited to 400 HP even with upgraded wiring and even then we'd recommend upgrading it anytime you are running more boost than stock.

Some things to consider when buying a fuel pump for your 3000GT or Dodge Stealth:

1)Wiring. Its usually required to run an extra relay to supply more power to the pump. It is recommended to use at least a 30 AMP relay with wire going directly to the battery and using the stock fuel pump voltage supply to turn the relay on. You should also do the resistor bypass under the good to be sure the relay is getting adequate trigger voltage (although they will usually work even 5 volts).

2)FPR and return. The stock fuel pressure regulator is known to overflow with larger pumps. It can either be upgraded or you can setup your system in a way that the pump runs at reduced voltage at idle, like the stock configuration. Some possiblities include using 2 stock resistor packs in parallel, but we'll leave this up to you.

The stock return line will support an aftermarket fuel pump with an upgraded FPR up to about the Walbro 450. It may overrun a bit even then. Some people upgrade their whole fuel system and use a 6AN return or the stock feed as a return.

Minor overrun can normally be delt with by tuning the fuel or even the stock ecu trims, but keep in mine you may see as high as 60 PSI base (stock is 43 vaccum disconnected), so it can be quite rich at idle.

3)Fuel hanger modifications. Its really easy to twist off the upper fuel pump fitting on top of the hat. Both because some people don't realize the nut doesn't turn on the hat line itself and also due to rust. A lot of people set these up with a 6an bulk head fitting, but if you can save the original line its best, because its a slippery slope.

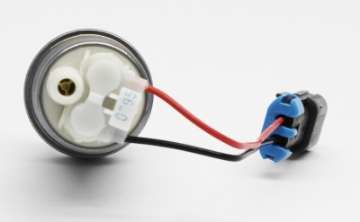

Unless you run a 100% stock drop in pump like an original turbo pump or a Toyota supra pump you will have to modify the hanger. Usually cutting off the bell in the metal line inside, adding a flare to that, and then using some in tank safe fuel line to connect to the fuel pump of choice. You then normally use a hose clamp to attach the pump to the original hat bracket, aiming for 3/8" to 1/2" of space for the pump sock and the bottom of the stock tank.

Working on your fuel system needs to be done with a lot of care, if you are not sure, consult us or a qualified mechanic. Don't take unsafe steps to repair your fuel system.